New Blow Moulding Technology facilitating Production of Two Products in different Material & Colours on the same Machine

Twin Material / Colour Blow Moulding Technology

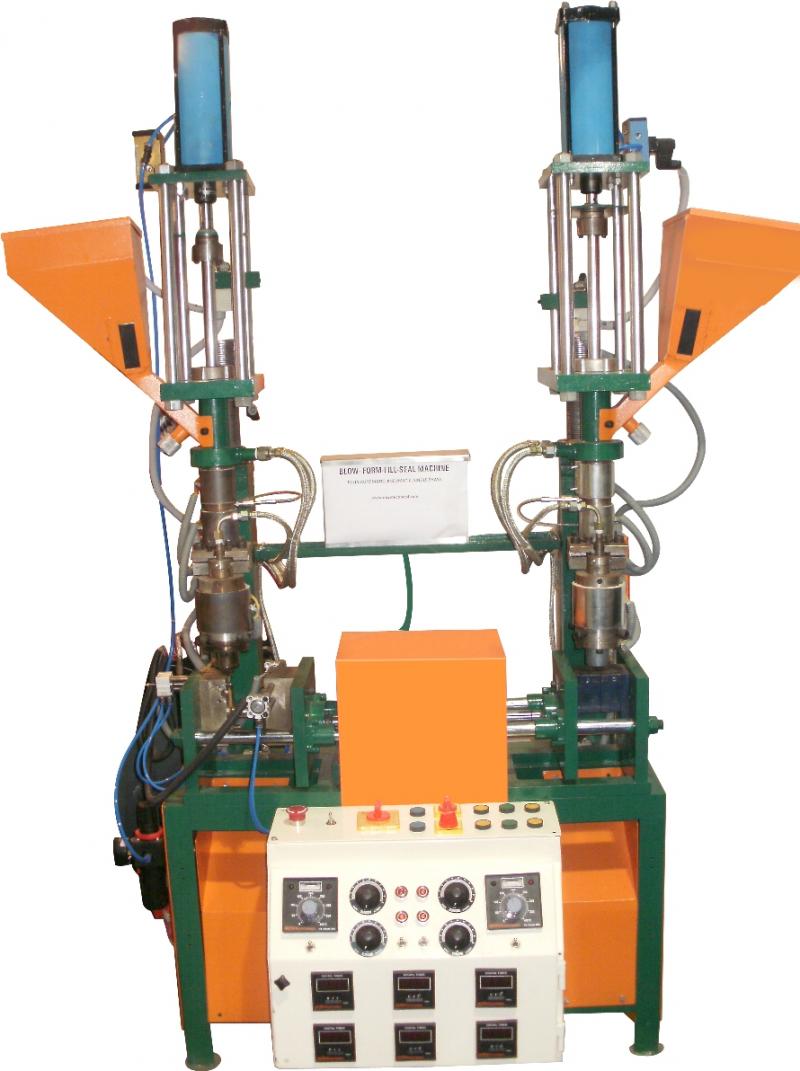

TWIN BLOW MACHINE

PATENT PROTECTED

Winners of 4th National Awards for Technology Innovations 2014

by

Ministry Department of Chemical & Petrochemicals – GOVT OF INDIA

under the category of Innovation of Polymer Processing Machinery and Equipment’s.

Continuing Innovations, Dave Technical Services offers World’s Smallest Fully Automatic, Pneumatic, double (Twin) station, Single Phase operated Blow Moulding (DSBM-01 Series) Machine in India.

The machine has two parison unit and offers for the first time in world Unique flexibility of producing 2 different products of different materials (polymers) having different shapes, size and thickness as required simultaneously at the same time on same machine. Even 2 products with different colours can be produced concurrently on this machine as required.

The Patent Protected Blow Moulding machine model is specially developed keeping in mind the customer’s requirement of low power consumption & smallest floor space utilization, providing efficiency, convenience and high productivity (profitability).

The machine is fully AUTOMATIC, PNEUMATIC (No Motor in the machine) works on air pressure (compressor) providing considerable power savings. The machine is adapted to operate on both Single phase as well as 3 phase power making it convenient to be installed even in Rural areas.

The Blow moulding machine model is very simple to operate & user friendly (eliminates high skilled operators & reduced man power requirements).

Ideal for fast production of small blown products, critical items that are not economical on large complex machines. Smallest component by volume / weight, products starting from 0.2 ml and thickness as low as 0.2 mm can be produced.

Machine with Option of Double Head on single or both stations for higher production output also available

Dave Technical Services also offers the optional choice of getting Filling & Sealing arrangement on the machine i.e. machine provides complete synchronization in forming of plastic product with arrangement for liquid filling (volumetric principle) and Sealing it.

The machines is suitable to handle wide product range on it to cater to various industry requirements by just changing molds as required on same set up.

Plastic polymers like LDPE, LLDPE, HDPE, Polypropylene, PS, HIPS, EVA, TPE others can be processed.

Applications: Products like Bottles & Containers, plastic bellows, toy parts, straws, tubes, float ball, cans, droppers and pipettes, Tools handle, single dose packs for Liquids, Semi Solids and many others. Packaging application for various industries like pharmaceutical, cosmetic, medical, chemicals, oral care, Agrochemicals, veterinary products and others

Features:

Fully Automatic with Simple Operations, Precise performance and Robust construction

Fully Pneumatic (No Motor in the machine)

Works on Air Compressor – provides considerable power savings

Adapted to operates on both Single or Three (3) phase power supply

Quick Mould Changes

Fitted with Universal platen – to accommodates bigger volume molds

Flexibility of producing Wide product range on same machine

Variable weight adjustment system in head.

Ideal for Entrepreneurs, Rural area installation, Industry development.

Option of PLC (micro processor) based controls available

Extrusion Blow machine models in 250ml, 500ml, 1 and 2 litres capacities available.

(All the intellectual property associated with this fully automatic, pneumatic, single phase, double station Blow moulding machine is rightly protected through patents, design registrations & copyrights. All rights are reserved with Dave Technical Services.)